DPC-70 पल्ट्रूडेड कूलिंग टावर्स

उत्पाद विवरण:

- मटेरियल

- एप्लीकेशन प्रक्रिया शीतलन, बिजली संयंत्र, रासायनिक, उर्वरक, प्रशीतन, प्लास्टिक, डिस्टिलरी, स्टील और अधिक

- उपयोग औद्योगिक, वाणिज्यिक

- शर्त

- बिजली की आपूर्ति बिजली

- वोल्टेज 440 वोल्ट (v)

- वारंटी इरेक्शन की तारीख से 12 महीने या डिलीवरी की तारीख से 15 महीने, जो भी पहले हो

- अधिक देखने के लिए क्लिक करें

DPC-70 पल्ट्रूडेड कूलिंग टावर्स मूल्य और मात्रा

- 1

- यूनिट/यूनिट

DPC-70 पल्ट्रूडेड कूलिंग टावर्स उत्पाद की विशेषताएं

- औद्योगिक, वाणिज्यिक

- प्रक्रिया शीतलन, बिजली संयंत्र, रासायनिक, उर्वरक, प्रशीतन, प्लास्टिक, डिस्टिलरी, स्टील और अधिक

- 440 वोल्ट (v)

- इरेक्शन की तारीख से 12 महीने या डिलीवरी की तारीख से 15 महीने, जो भी पहले हो

- बिजली

DPC-70 पल्ट्रूडेड कूलिंग टावर्स व्यापार सूचना

- 30 प्रति महीने

- 6-8 हफ़्ता

उत्पाद वर्णन

DeleteDPC 70

Product Description

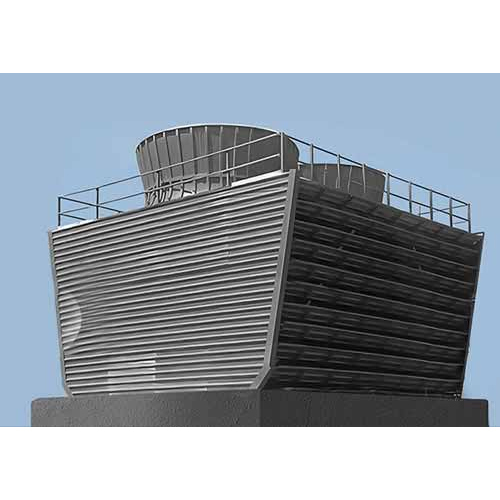

DPC-70 SeriesPultruded FRP Cooling Towers by Delta Cooling Towers Pvt. Ltd. are engineered for high-end industrial cooling applications where structural longevity, corrosion resistance, and mechanical strength are paramount. These towers are built using high-performancePultruded FRP sectionsthat provide superior structural rigidity compared to conventional materials.

The DPC-70 towers are designed using theInduced Draft Counter Flowprinciple, allowing optimal heat transfer in minimal space. The Pultruded FRP structure ensures excellent resistance to chemical exposure, harsh weather conditions, and industrial environments, making it ideal for power plants, steel units, petrochemical facilities, fertilizers, and heavy-duty process industries.

The tower incorporates astatic piping system with polypropylene nozzles, depending on design. The high-efficiency fills and axial flow fans ensure maximum contact between air and water, resulting in effective cooling with minimal drift and noise. These towers are available inmodular multi-cell configurations, suitable for scalable installations.

The DPC-70 Series is built to deliver durability, low maintenance, and high performance. It is ideal for clients seeking reliable, long-term cooling tower solutions that align withmodern industry standards and safety norms.

Other Details:

| Feature | Specification |

|---|---|

| Usage | Industrial |

| Condition | New |

| Casing Material | FRP |

| Structure Material | Pultruded FRP Sections |

| Water Distribution | Static header with PP Nozzles as per design |

| Fills | PVC Honeycomb / LPS / Opti Grid / Trickle as per design |

| Motor | TEFC / TEAO with IP55 Protection |

| Fan Material | FRP / Aluminum |

| Power Supply | Electric |

| Electrical Characteristics | 440V / 50 Hz / 3 Phase |

| Heat Transfer Method | Wet Evaporative Cooling |

| Circuit | Open Circuit |

| Build | Field Erected |

| Air Drawing Method | Induced Draft |

| Air Movement Method | Counter Flow |

| Applications | Process Cooling, Power Plants, Chemical, Fertilizers, Refrigeration, Plastic, Distilleries, Steel & more |

| Cooling Tower Type | Induced Draft Counter Flow |

| Usage | Industrial |

| Warranty | 12 months from the date of erection or 15 months from the date of delivery, whichever is earlier |

| Condition | New |

| Number of Cells | Single and Multi-cell |

| Design | Modular |

| Range | 50 cubeM/Hr to Unlimited |

| Exclusions | Foundation, Basin, External Piping, Pumps, Valves, Starters, etc. |

Trade information:

| Payment Terms | 35% advance with order, balance against pro-forma invoice before dispatch |

|---|---|

| Supply Ability | 30 Units Per Month |

| Delivery Time | 6-8 weeks (depending on capacity) |

| Erection Time | 5-7 days (depending on capacity) |

| Export Market | Worldwide |

| Main Domestic Market | All India |

Frequently Asked Questions (FAQs): DPC-70 Series Pultruded FRP Cooling Towers

Q1: What distinguishes the DPC-70 Series from standard FRP cooling towers?

A1: The DPC-70 Series features a Pultruded FRP supporting structure, offering superior strength, chemical resistance, and durability, especially suitable for harsh industrial environments.

Q2: What is the operating principle of the DPC-70 Series?

A2: It operates on the Induced Draft Counter Flow principle, drawing air upward using axial flow fans and distributing water via a static or rotary distribution system.

Q3: What capacities are available in the DPC-70 Series?

A3: The DPC-70 towers are available from 50 M3/Hr to unlimited, with custom multi-cell configurations.

Q4: Can these towers be customized for project-specific requirements?

A4: Yes, DPC-70 towers are modular and can be tailored to match your cooling load, site layout, and operational needs.

Q5: What certifications does the DPC-70 Series come with?

A5: Delta Cooling Towers is ISO 9001 and ISO 14001 certified and recognized under the MSME ZED scheme. The DPC-70 Series follows stringent internal quality assurance protocols.

Q6: What industries commonly use Pultruded FRP Cooling Towers?

A6: DPC-70 towers are widely used in chemical industries, fertilizers, power plants, pharmaceuticals, sugar mills, steel processing and many more.

Q7: How is the water distributed inside the tower?

A7: Water is distributed either through a static header with Nozzles, depending on design preference.

Q8: What is the electrical specification of the DPC-70 towers?

A8: The standard operating voltage is 440V / 50Hz / 3Ph. Other voltage configurations can be provided on request.

Q9: How are these cooling towers delivered?

A9: These cooling towers are dispatched in loose components for site assembly.

Q10: What is the warranty period?

A10: 12 months from the date of erection or 15 months from the date of delivery, whichever comes first.

Q10: Is a water basin included with the DPC-70 series cooling towers?

A10:Typically, DPC-70 series cooling towers are supplied without a basin. It is recommended that the customer construct an RCC basin at the installation site. However, for smaller capacity models, an FRP basin can be provided upon request.

Price: Â

- 50

- 100

- 200

- 250

- 500

- 1000+

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese