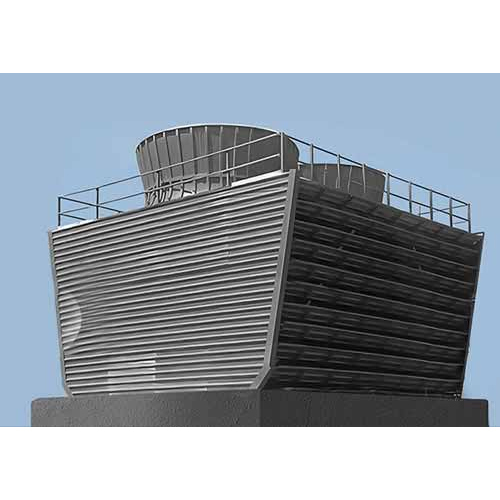

DFC-50 Round Cooling Towers

उत्पाद विवरण:

- उपयोग औद्योगिक, वाणिज्यिक

- एप्लीकेशन स्वच्छ वातावरण और उपचारित पानी के साथ एचवीएसी, प्लास्टिक, प्रक्रिया और अनुप्रयोग

- मटेरियल एफ आर पी

- शर्त नया

- बिजली की आपूर्ति बिजली

- वोल्टेज 440 वोल्ट (v)

- नोजल सामग्री पॉलीप्रोपाइलीन स्पलैश कप

- अधिक देखने के लिए क्लिक करें

DFC-50 राउंड कूलिंग टावर्स मूल्य और मात्रा

- यूनिट/यूनिट

- यूनिट/यूनिट

- 1

DFC-50 राउंड कूलिंग टावर्स उत्पाद की विशेषताएं

- पॉलीप्रोपाइलीन स्पलैश कप

- नया

- एफ आर पी

- स्वच्छ वातावरण और उपचारित पानी के साथ एचवीएसी, प्लास्टिक, प्रक्रिया और अनुप्रयोग

- इरेक्शन की तारीख से 12 महीने या डिलीवरी की तारीख से 15 महीने, जो भी पहले हो

- बिजली

- 440 वोल्ट (v)

- औद्योगिक, वाणिज्यिक

DFC-50 राउंड कूलिंग टावर्स व्यापार सूचना

- कैश इन एडवांस (CID)

- 50 प्रति महीने

- 6-8 हफ़्ता

- एशिया ऑस्ट्रेलिया पश्चिमी यूरोप मिडल ईस्ट मध्य अमेरिका उत्तरी अमेरिका दक्षिण अमेरिका पूर्वी यूरोप अफ्रीका

- ऑल इंडिया

उत्पाद वर्णन

Product Description

The DFC-50 Series Round FRP Cooling Towers by Delta Cooling Towers Pvt. Ltd. are engineered for optimal performance in industrial cooling applications. Designed using the Induced Draft Counter Flow principle, these towers ensure efficient heat dissipation while maintaining a compact, circular footprint that offers 360-degree air intake. The tower body is made of high-quality FRP (Fiberglass Reinforced Plastic), providing excellent structural strength, corrosion resistance, and long service life even in harsh environmental conditions.

At the heart of the DFC-50 design is a rotary sprinkler system made of aluminum, which uniformly distributes water over the fill media to ensure consistent cooling across all flow rates. The fill is carefully selected for maximum surface area and efficient water-air contact, improving thermal performance. A direct-driven axial flow fan, mounted on a weather-resistant motor, ensures high airflow with low noise and energy consumption.

The supporting structure is constructed using hot-dip galvanized mild steel (MS), ensuring strong mechanical support and resistance to rust. The DFC-50 towers are easy to install and maintain, with most models below 20 TR shipped in completely knocked-down (CKD) condition, while higher-capacity models are shipped in component form for on-site assembly.

These towers operate on 440 V / 50 Hz, and can be customized to suit country-specific voltage requirements. They come with a warranty of 12 months from the date of erection or 15 months from the date of delivery, whichever is earlier.

With their robust design, quiet operation, and adaptability to diverse industrial conditions, the DFC-50 Series towers are widely used in sectors such as plastics, pharmaceuticals, HVAC, distilleries, and general manufacturing. Combining engineering excellence with reliability, the DFC-50 Series continues to be a preferred choice for industries seeking compact and efficient cooling solutions.

Trade Information:

Frequently Asked Questions (FAQs)

FAQs - DFC-50 Series Round FRP Cooling Towers

Q1: What cooling technology is used in the DFC-50 Series?

A1: The DFC-50 Series operates on the Induced Draft Counter Flow principle, offering efficient thermal performance and dependable operation across various industrial applications.

Q2: What is the operating voltage of the DFC-50 Cooling Towers?

A2: The standard operating voltage is 440 V / 50 Hz. However, motors can be supplied as per country-specific voltage and frequency standards, on request.

Q3: What is the construction material of the cooling tower body?

A3: The cooling tower body is made of FRP (Fiberglass Reinforced Plastic), known for its strength, lightweight, and excellent corrosion resistance.

Q4: What is the material used for the supporting structure?

A4: The supporting structure is manufactured from hot-dip galvanized mild steel (MS) to ensure structural integrity and long-lasting performance.

Q5: What kind of water distribution system does the DFC-50 use?

A5: It uses an aluminium rotary sprinkler system that rotates with water pressure and evenly distributes water over the fill media.

Q6: Are nozzles used in this cooling tower?

A6: No. The DFC-50 Series uses a rotary sprinkler and does not include any nozzles.

Q7: Is the DFC-50 a modular cooling tower?

A7: No. The DFC-50 is a single-cell, non-modular unit and is not available in customizable configurations.

Q8: What is the condition of the product when delivered?

A8: The product is supplied in brand new condition, manufactured to order under stringent quality control standards.

Q9: What is the warranty offered with the DFC-50 Cooling Towers?

A9: The warranty is 12 months from the date of erection or 15 months from the date of delivery, whichever comes earlier.

Q10: Is the DFC-50 Series certified?

A10: Delta Cooling Towers Pvt. Ltd. is an ISO 9001 and ISO 14001 certified company and is also registered under the MSME ZED (Zero Defect Zero Effect) scheme.

Q11: How is the DFC-50 Cooling Tower shipped?

A11: Units with capacity less than 20 TR are typically shipped in Completely Knocked Down (CKD) condition. Larger capacity units are dispatched in loose component form and assembled at the site.

Q12: What industries commonly use the DFC-50 Series?

A12: The DFC-50 Series is suitable for plastics, pharmaceuticals, food processing, HVAC systems, distilleries, and other small-to-medium industrial cooling applications.

Price: Â

- 50

- 100

- 200

- 250

- 500

- 1000+

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese